Here are pictures of a combustion chamber during different stages of porting the heads.

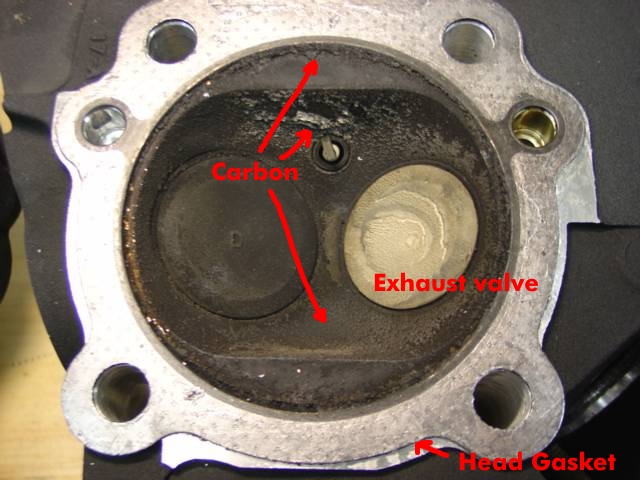

In the first picture you can see a head that was removed and shipped to us. It still has the head gasket on. Note the carbon build up in the combustion chamber. Also the burnt on carbon on the exhaust valve. The exhaust valve is the hottest part of the engine. This particular head was off a stock bike with 15,000 miles.

This is a picture of a new take off head. It only has a couple miles on it from when it was run at the factory. Inside the combustion chamber is the same powder coating as the rest of the head. HD takes the fresh cast heads and powder coats the entire casting. Then they machine all the surfaces and install all the parts, ie guides, valve seats, exhaust studs etc. The head gasket surface on this head is very clean, this is because it has been milled to correct the compression ratio.

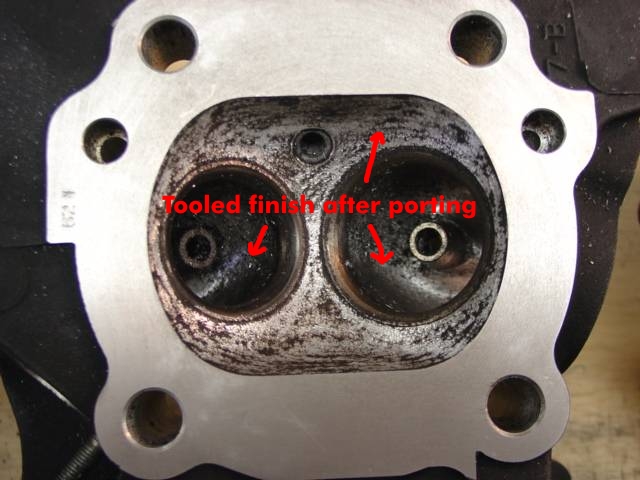

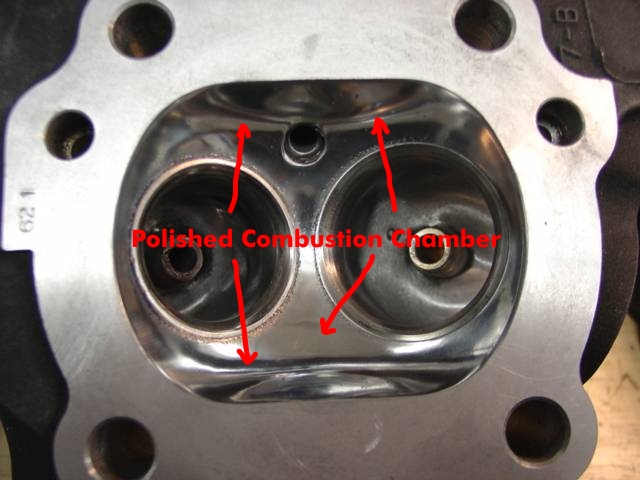

Here is a head after porting. The intake and exhaust ports have been reshaped and all the carbon and powder coat removed from the combustion chamber.

v

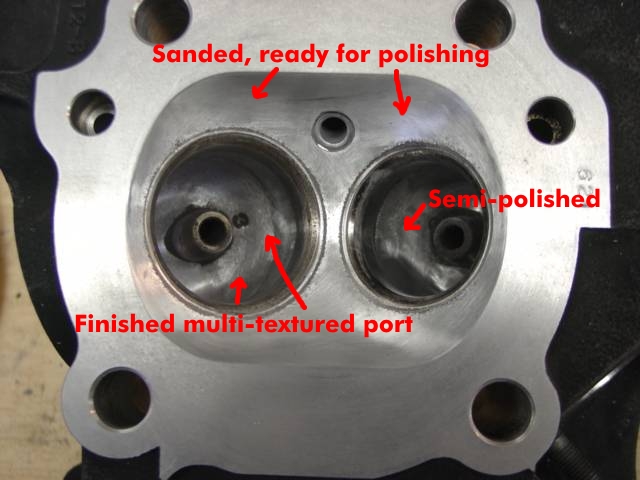

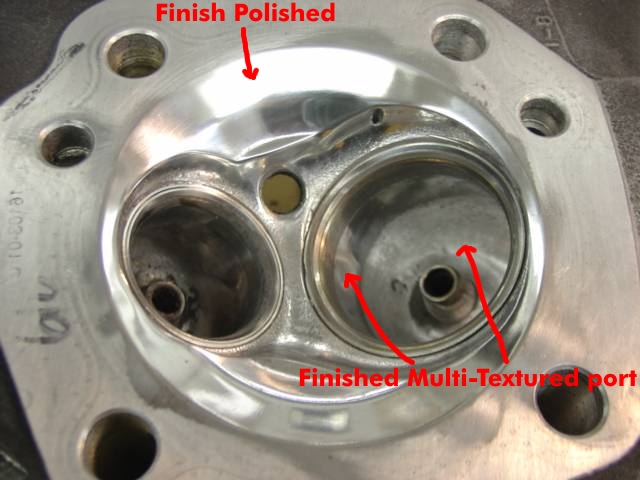

After all the porting process, the head is sanded to the appropriate grits. The intake, exhaust and combustion chamber all recieve a different surface finish.

The combustion chamber is polished to help reflect heat into the charge and to help reduce future carbon build up.

Here we have an HTCC non ported head, that has been ported by Bean. The black sharpie lines are to indicate the quench area. The piston has a similar shape. Note the rough cut ports.

The same HTCC head after porting and polishing. Note the finished ports.

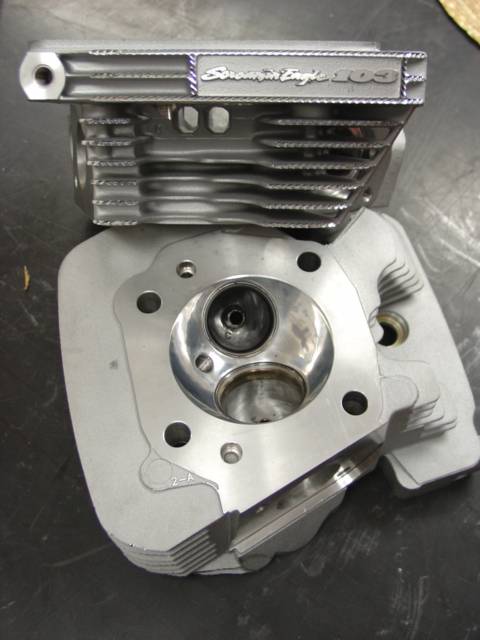

This is a Screamin Eagle 103 head. Note the silver powder coat in the combustion chambers and in the ports, same as a stock head. This is a brand new never run head. It was sent out for diamond cut and then sent in for milling and porting. Note the sharpie mark indicating milling .060".

The completed Screamin Eagle 103 head.

The completed set.